What is GI/GP?

GI sheet stands for “Galvanized Iron” sheet, is a type of steel sheet that has been coated with a layer of zinc to protect it from corrosion. The process of applying a zinc coating to steel is known as galvanization, and it helps to prevent the underlying steel from rusting. Owing to its superior resistance to corrosion and attractive look, it is an economical option for use in construction, automotive, furniture, household appliances, white goods, and HVAC, etc.

What is GI Sheet?

GI sheet stands for “Galvanized Iron” sheet, is a type of steel sheet that has been coated with a layer of zinc to protect it from corrosion. The process of applying a zinc coating to steel is known as galvanization, and it helps to prevent the underlying steel from rusting. Owing to its superior resistance to corrosion and attractive look, it is an economical option for use in construction, automotive, furniture, household appliances, white goods, ducting, etc.

What is GPSP ?

GPSP sheet stands for “Galvanized Plain Skin Pass” sheet, likely refers to galvanized steel sheets that have undergone a skin pass process. The skin pass not only improves the surface finish but also imparts certain mechanical properties to the steel sheet. It can enhance the flatness, weldability, paint adherance, surface appearance, and overall quality of the galvanized steel product, making it suitable for various applications, such as roofing, automotive components, construction and powder coating, clean rooms, Structures, Clamps, Handicrafts and Silos.

What is ZM (Posmac)?

ZM sheet stands for “Zinc Magnesium” sheet, a modern marvel with coating of Zinc 91% + Aluminum 6% + Magnesium 3%. ZM brings innovation to engineering and architectural landscapes. A protective layer is formed over Zn layer which gives way higher corrosion resistance than only zinc coated material, this layer is called Zinc chloride hydroxide monohydrate is a zinc hydroxy compound with chemical formula Zn₅(OH)₈Cl₂·H₂O. This coating defend structures against the relentless forces of rust and decay.

This is a very good product for highly corrosive environment such as costal areas or chemical industries. It has a wonderful property of covering exposed cut surfaces with same protective layer. It has a coating way stronger than only zn coated material. It is a highly regarded material for solar and poultry industry.

What is GL?

GL stands for galvalume or zincalume and has coating of zinc + Aluminum. Galvalume sheets are a revolutionary construction material, combining the strength of steel with the corrosion-resistant properties of aluminum-zinc alloy. Comprising zinc, aluminum, and silicon, these sheets offer unparalleled durability and weather resistance. Widely used in roofing and cladding applications, Galvalume sheets provide an enduring shield against rust, ensuring structures withstand harsh environmental conditions.

With a distinctive metallic finish, they not only enhance the aesthetic appeal of buildings but also contribute to sustainability efforts due to their long lifespan and recyclability. Galvalume sheets stand as a testament to the seamless integration of strength, resilience, and environmental consciousness in modern construction practices.

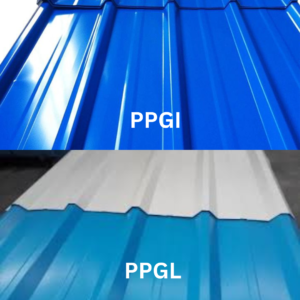

What is PPGL / PPGI?

PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) are both coated steel products used in construction. The key difference lies in the coating material. PPGI is coated with Zinc, providing excellent corrosion resistance. In contrast, PPGL employs a zinc-aluminum alloy (typically Galvalume), enhancing durability and heat resistance. PPGL is well-suited for harsh environments. Both offer a wide range of colors, textures and finishes, adding aesthetic value to structures.

The choice between PPGI and PPGL depends on specific project requirements, with PPGL often preferred for extended longevity and enhanced performance in challenging conditions. PPGI is preferred in white goods industry and industries who want to make cheap finished good on the other hand PPGL is being used as preferred choice for roofing and cladding applications.